Check out the incredible deals on some of DeWALT's most popular tools and kits below. Limited quantities available, prices valid only while supplies last.

Check out the incredible deals on some of DeWALT's most popular tools and kits below. Limited quantities available, prices valid only while supplies last.

Whether you're constructing an educational institution, healthcare facility, or government building, you can count on Simpson Strong-Tie for a wide range of commercial construction products that have been rigorously tested for durability and adaptability.

From structural and cold-formed steel to mechanical and adhesive anchors, along with code-compliant connectors and fastening systems, Mudge Fasteners and Simpson Strong-Tie can provide everything necessary to create stronger, safer buildings.

Mudge Fasteners is your partner for Simpson Strong-Tie products. We will ensure you receive the right product and timely job site delivery. We get it right, right on time.

You can utilize Simpson’s technical support tools, like their Anchor Designer and Cartridge Calculator, that are featured in our Technical Support section. For pricing or more information on Simpson Strong-Tie products, contact Mudge Fasteners at (800) 634-0406.

When it comes to construction and industrial fastening solutions, efficiency, strength, and durability are crucial. This is where SFS Flex5® self-drilling fasteners stand out. Designed to streamline installation while maintaining high-performance standards, these fasteners are an excellent choice for both professionals and DIY enthusiasts. But what makes them so special? Let’s explore why you should consider SFS Flex5® self-drilling fasteners for your next project.

Features and Benefits

Made from alloy steel and finished with a selective hardness heat treatment process to give the load bearing part of the fastener Grade 5 specifications (RC 26-34), with a higher hardness for the drill point and lead-in threads (min. RC52).

Increased fastener ductility helps prevent hydrogen embrittlement

Designed to have low driving and thread engagement torque and provide maximum clamp load

Listed on Intertek Evaluation Report CCRR-0347

1. No Pre-Drilling Required: Save Time and Effort

One of the biggest advantages of SFS Flex5® self-drilling fasteners is their ability to eliminate the need for pre-drilling. These fasteners feature a sharp drilling point that cuts through metal or wood surfaces on its own, making the installation process much quicker and more efficient. Whether you're working with metal-to-metal or metal-to-wood connections, these fasteners reduce the steps in your workflow and minimize the time spent switching between tools.

2. Superior Strength and Durability

The SFS Flex5® line is engineered for strength, ensuring that the fasteners can handle demanding structural applications. Made from high-quality materials, these fasteners are designed to resist wear and tear over time, maintaining their integrity even in harsh conditions. This durability makes them a reliable solution for projects that require long-lasting fastening power, such as roofing, metal framing, or industrial builds.

3. Wide Range of Sizes for Versatile Applications

No two projects are the same, and neither are their fastening requirements. Fortunately, SFS Flex5® self-drilling fasteners come in a wide range of sizes, from short fasteners ideal for thin metal sheets to longer options that can handle thicker materials. This versatility ensures that you can find the perfect fastener for your specific project, regardless of the material thickness or structural demands.

4. Corrosion Resistance for Longevity

In many construction and industrial applications, fasteners are exposed to moisture, temperature changes, and other environmental factors that can lead to rust and corrosion. SFS Flex5® self-drilling fasteners are coated with vistaCorr, a proprietary coating providing improved appearance, corrosion resistance, durability and installation performance. Salt spray per ASTM B117 - 1,000 hrs.

5. Cost-Effective in the Long Run

While it’s tempting to go with cheaper fasteners, investing in high-quality options like the SFS Flex5® line pays off in the long run. With their durability and corrosion resistance, these fasteners reduce the need for frequent replacements or repairs. Moreover, the time saved on installation due to their self-drilling feature adds up, especially in larger projects, making them a cost-effective solution overall.

6. Optimized for Safety and Performance

SFS Flex5® fasteners are designed with safety in mind. Their consistent drilling performance ensures that they penetrate materials cleanly and securely, reducing the risk of improper fastening that can lead to structural failures. Whether you're working on a high-stakes construction project or a simpler home renovation, having fasteners you can trust is essential for safety and success.

SFS Flex5® self-drilling fasteners offer a winning combination of efficiency, strength, and reliability. By eliminating the need for pre-drilling, providing excellent corrosion resistance, and offering a variety of sizes, these fasteners can adapt to any project with ease. Whether you're tackling a commercial construction task or working on a smaller DIY project, SFS Flex5® self-drilling fasteners ensure that your job is done right the first time, saving you time and money in the long run. All SFS Flex5® self-drilling fasteners are proudly Made in the USA.

Consider using SFS Flex5® self-drilling fasteners for your next project to experience the benefits of high-performance fastening firsthand! For pricing or more information, contact Mudge Fasteners at (800) 634-0406.

SFS Flex5® self-drilling fasteners come in a variety of sizes to meet different application needs, offering flexibility for various construction and industrial projects. These fasteners are available in lengths typically ranging from 1/2 inch to 6 inches, with diameters commonly varying between #8 and #14. The specific size of the fastener needed depends on the thickness of the materials being fastened and the overall structural requirements. With their self-drilling capability, Flex5® fasteners eliminate the need for pre-drilling, making them highly efficient for fastening metal to metal or metal to wood. Their variety of sizes ensures adaptability for light to heavy-duty tasks, providing a reliable and durable fastening solution.

All SFS Flex5® self-drilling fasteners are proudly Made in the USA.

For pricing or more information, contact Mudge Fasteners at (800) 634-0406.

SFS Flex5® self-drilling fasteners are constructed from alloy steel and undergo a specialized heat treatment process to ensure selective hardness. This treatment provides grade 5 specification performance (RC 26-34) for the load-bearing section of the fastener, while the drill point and lead-in threads are hardened to a minimum of RC 52 to enable effective drilling and tapping into steel. The reduced hardness in the load-bearing region enhances the fastener's ductility, reducing the risk of embrittlement failure.

Applications

Curtain wall applications

Rainscreen and cladding

Faster fastening than a traditional Grade 5 bolt and nut

All fenestration systems

Solar panel systems connecting aluminum to steel

Dissimilar metal applications when used with aluminum

All SFS Flex5® self-drilling fasteners are proudly Made in the USA.

For pricing or more information, contact Mudge Fasteners at (800) 634-0406.

MP35N Fasteners

MP35N is a high-performance nickel-cobalt-based alloy known for its exceptional mechanical properties, including high strength, excellent corrosion resistance, and biocompatibility. The alloy is composed of approximately 35% nickel, 35% cobalt, 20% chromium, and 10% molybdenum, with small amounts of other elements.

Key Properties of MP35N:

High Strength and Toughness: MP35N is capable of achieving very high strength levels while maintaining good toughness. It can be cold-worked to increase its strength further, making it ideal for components subjected to high mechanical stress.

Corrosion Resistance: The alloy offers excellent resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes it suitable for use in harsh environments, including those encountered in the human body.

Biocompatibility: MP35N is biocompatible, meaning it is non-toxic and does not elicit an adverse reaction when in contact with human tissues. This is crucial for medical applications.

Fatigue Resistance: The alloy has excellent fatigue resistance, which is important for components that undergo repetitive loading, such as fasteners in medical devices.

Non-Magnetic: MP35N is non-magnetic, which can be beneficial in certain medical applications where magnetic interference must be minimized.

Why MP35N is a Good Material for Medical Device Fasteners:

Durability: Medical device fasteners need to maintain their integrity under various mechanical loads, and MP35N's high strength and toughness ensure that they can withstand these conditions without failure.

Corrosion Resistance: Medical devices often operate in environments where exposure to bodily fluids or sterilization processes could lead to corrosion. MP35N’s excellent corrosion resistance ensures that the fasteners remain reliable over time.

Biocompatibility: Fasteners made from MP35N are safe to use in contact with the body, reducing the risk of adverse reactions and ensuring patient safety.

Long-term Reliability: The alloy’s resistance to fatigue and wear ensures that the fasteners will perform effectively over long periods, which is particularly important for implanted devices.

Non-Magnetic Properties: In certain medical applications, such as those involving MRI machines, non-magnetic materials are necessary to prevent interference. MP35N meets this requirement, making it suitable for a range of medical devices.

These properties make MP35N an ideal choice for medical device fasteners, particularly in critical applications where performance, reliability, and safety are paramount.

For pricing or more information about MP35N fasteners, contact Mudge at (800) 634-0406.

PEEK Pan Head Phillips Machine Screw

Polyether Ether Ketone (PEEK) is a high-performance thermoplastic polymer known for its exceptional mechanical properties, chemical resistance, and biocompatibility. Here's an overview of PEEK and why it's an excellent choice for fasteners in medical devices:

Key Properties of PEEK:

High Strength and Stiffness: PEEK exhibits excellent mechanical strength and rigidity, making it suitable for demanding applications where durable and reliable fasteners are required.

Temperature Resistance: PEEK maintains its mechanical properties over a wide temperature range, from -70°C to 250°C. This makes it suitable for sterilization processes, including autoclaving, which is common in medical environments.

Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, including aggressive cleaning agents and bodily fluids. This ensures that fasteners made from PEEK will not degrade or corrode over time when exposed to these substances.

Biocompatibility: PEEK is biocompatible, meaning it does not produce any adverse biological reactions when in contact with human tissue. This is crucial for medical applications, as fasteners may come into contact with or be implanted in the body.

Low Weight: PEEK is lightweight compared to metals, which is advantageous in reducing the overall weight of medical devices.

Wear and Fatigue Resistance: PEEK exhibits excellent wear resistance and can withstand repetitive stress, making it ideal for fasteners that need to endure long-term use without failure.

Radiolucency: PEEK is radiolucent, meaning it does not interfere with imaging techniques such as X-rays or MRI scans. This property is beneficial for medical devices, as it allows for clear imaging without artifacts caused by metal fasteners.

High-Strength Options

For applications requiring enhanced strength and rigidity, PEEK screws can be reinforced with glass or carbon fibers. These reinforced fasteners provide increased mechanical durability, making them particularly suitable for use in environments exceeding 350°F (175°C).

100% Pure PEEK (Unfilled): Unfilled PEEK, made entirely of polymer with no added fillers, is one of the strongest polymers available. Despite lacking glass or carbon fiber reinforcement, it remains highly versatile and is ideal for applications requiring high purity, such as FDA-compliant food contact situations.

PEEK with Glass Fiber Reinforcement: This variant maintains the chemical resistance of natural PEEK but significantly boosts tensile strength, nearly doubling it.

PEEK with Carbon Fiber Reinforcement: This option offers about 2.5 times the strength of pure PEEK, making it an excellent choice for the most demanding applications.

Why PEEK is Ideal for Medical Fasteners:

Durability: The strength and resistance to wear and fatigue make PEEK fasteners reliable over long periods, even in challenging environments like the human body.

Biocompatibility: The ability of PEEK to be used safely in direct contact with body tissues ensures that it meets the stringent safety requirements for medical devices.

Chemical and Sterilization Resistance: Fasteners in medical devices often need to withstand aggressive cleaning processes and exposure to various chemicals, all of which PEEK can handle without degrading.

Lightweight: Reducing the weight of medical devices can improve patient comfort and ease the handling and transport of these devices by medical professionals.

Overall, PEEK's combination of mechanical strength, chemical resistance, biocompatibility, and other properties make it a superior choice for fasteners in medical devices. These attributes ensure that the fasteners will perform reliably in demanding medical environments, contributing to the safety and efficacy of the devices in which they are used.

For pricing or more information on Polyether Ether Ketone fasteners, contact us at (800) 634-0406.

PTFE Hex Bolt

PTFE (Polytetrafluoroethylene) is a synthetic fluoropolymer of tetrafluoroethylene, commonly known by the brand name Teflon. Fasteners made from PTFE (Polytetrafluoroethylene) are specialized components used in various applications, including medical devices, where their unique properties offer significant advantages. Here’s a deeper look into PTFE fasteners:

Types of PTFE Fasteners

Screws: PTFE screws are often used in assemblies where chemical resistance and non-reactivity are crucial. They are commonly used in medical devices, electronics, and chemical processing equipment.

Nuts: PTFE nuts are used in conjunction with PTFE bolts or screws. They provide excellent sealing properties and are often used in applications requiring a tight, leak-proof connection.

Washers: PTFE washers are used to distribute the load of a threaded fastener and to provide a smooth, non-reactive surface. They are especially useful in environments where a non-stick or low-friction surface is needed.

Bolts: PTFE bolts offer high strength while maintaining the non-reactive and non-corrosive properties of PTFE. They are ideal for use in medical devices where the material’s properties are needed to prevent contamination or chemical reactions.

Key Advantages of PTFE Fasteners

Corrosion Resistance: PTFE fasteners are highly resistant to corrosion and degradation caused by exposure to harsh chemicals, acids, and bases. This is critical in medical environments where sterilization and chemical exposure are frequent.

Non-Reactivity: PTFE does not react with most chemicals, ensuring that fasteners will not degrade or cause contamination in sensitive applications, such as in medical devices or laboratory equipment.

Low Friction: The low friction coefficient of PTFE reduces wear and tear on fasteners, making them ideal for applications where smooth operation and long-term durability are required. This is particularly beneficial in moving parts of medical devices.

Temperature Resistance: PTFE fasteners can withstand extreme temperatures, both hot and cold, without losing their structural integrity. This makes them suitable for use in medical devices that may undergo sterilization processes involving high temperatures.

Electrical Insulation: PTFE is an excellent insulator, so fasteners made from this material are used in applications requiring electrical isolation, which can be important in certain medical and electronic devices.

Biocompatibility: PTFE is biocompatible, meaning it is safe to use in applications involving direct contact with human tissues. This property is essential for medical devices, especially those that are implanted or come into prolonged contact with the body.

Applications of PTFE Fasteners in Medical Devices

Implants: PTFE fasteners are sometimes used in implantable medical devices due to their biocompatibility and non-reactive nature.

Surgical Instruments: PTFE fasteners are used in surgical instruments where precision, durability, and resistance to sterilization processes are crucial.

Diagnostic Equipment: In diagnostic equipment, PTFE fasteners ensure that the devices remain free from contamination and maintain their functionality over time.

Fluid Handling Systems: PTFE fasteners are ideal for use in fluid handling systems within medical devices, where chemical resistance and leak-proof connections are critical.

Limitations

Mechanical Strength: While PTFE is strong enough for many applications, it may not be as strong as some metals, which can be a limitation in high-stress environments.

Cost: PTFE fasteners can be more expensive than those made from conventional materials, which might be a consideration depending on the application.

In conclusion, PTFE fasteners are a key component in many advanced medical devices due to their exceptional chemical resistance, biocompatibility, low friction, and non-reactivity. They ensure the safety, reliability, and longevity of medical devices, especially in environments where exposure to chemicals, bodily fluids, and extreme temperatures is common.

If you’d like pricing or more information on PTFE fasteners for medical device manufacturing, contact Mudge Fasteners at (800) 634-0406.

Mudge Fasteners is a leader in the distribution of fasteners to the medical device manufacturing industry. In addition to a wide selection of premium products, our medical device customers love us for our Chain of Custody (CoC) documentation services.

Chain of Custody documentation is a detailed record that traces the possession, handling, and location of an item throughout its lifecycle. In the context of medical device fasteners, CoC documentation is critically important for several reasons:

1. Traceability

Accountability: Ensures that every entity handling the fastener, from manufacture to end use, is accountable.

Tracking: Provides a clear history of the fastener, including manufacturing details, quality checks, and distribution.

2. Quality Assurance

Compliance: Helps in meeting regulatory requirements and standards set by bodies like the FDA or ISO.

Consistency: Ensures that the fasteners meet specific quality and safety standards throughout the supply chain.

3. Safety

Preventing Contamination: Minimizes the risk of contamination and ensures that the fasteners are handled in a controlled environment.

Patient Safety: Critical for maintaining the safety and efficacy of medical devices, which directly impacts patient health.

4. Recalls and Investigations

Efficient Recalls: Facilitates swift and efficient recalls if a defect or issue is identified.

Root Cause Analysis: Aids in identifying the root cause of any issues or failures, allowing for corrective actions to be implemented.

5. Regulatory Compliance

Documentation: Required by regulatory agencies to ensure that medical device manufacturers comply with legal and safety standards.

Audits: Essential during regulatory audits and inspections to demonstrate compliance and traceability.

6. Supply Chain Integrity

Trust: Builds trust between manufacturers, suppliers, and healthcare providers.

Verification: Allows verification of the origin and handling of the fasteners, ensuring they have not been tampered with.

In summary, Chain of Custody documentation is essential for maintaining the integrity, quality, and safety of medical device fasteners, ensuring compliance with regulations, and protecting patient health. For more information about Chain of Custody documentation, contact Mudge Fasteners at (800) 634-0406.

Accubrace Brochure

Having reliable and efficient bracing systems is crucial for ensuring the stability and safety of precast concrete structures. Dayton Superior’s Accubrace System is a leading solution designed to meet these needs with precision and ease. This innovative system has gained popularity for its remarkable features, benefits, and versatile applications. In this blog post, we will delve into the specifics of the Accubrace System, exploring how it can enhance your construction projects.

Features of the Accubrace System

The Accubrace System is engineered with several standout features that make it an ideal choice for construction professionals:

High-Strength Components: The system is made from robust, high-quality materials designed to withstand significant loads and stresses. This ensures the stability and safety of precast concrete elements during the critical phases of construction.

Adjustability: One of the key features of the Accubrace System is its adjustability. The braces can be fine-tuned on-site to accommodate various project requirements, ensuring a perfect fit and alignment every time.

Ease of Installation: The Accubrace System is designed for quick and straightforward installation. Its user-friendly design reduces labor time and complexity, allowing for a faster and more efficient setup.

Versatility: This system is versatile and can be used for a wide range of applications, including walls, panels, columns, and beams. Its adaptability makes it suitable for various types of construction projects, from residential to commercial and industrial.

Benefits of Using the Accubrace System

Implementing the Accubrace System in your construction projects offers numerous benefits:

Enhanced Safety: The high-strength components and reliable design of the Accubrace System significantly enhance the safety of construction sites. The system provides robust support for precast concrete elements, minimizing the risk of accidents and structural failures.

Improved Efficiency: The ease of installation and adjustability of the Accubrace System contribute to improved efficiency on-site. By reducing the time and effort required for setup, the system helps keep projects on schedule and within budget.

Precise Alignment: The adjustable nature of the Accubrace System ensures precise alignment of precast concrete elements. This precision is crucial for maintaining the structural integrity and aesthetic quality of the final construction.

Cost-Effective: By streamlining the installation process and reducing labor costs, the Accubrace System proves to be a cost-effective solution for construction projects. Its durability and reusability further add to its economic advantages.

Uses of the Accubrace System

The versatility of the Accubrace System allows it to be used in a variety of construction scenarios:

Precast Concrete Walls: The Accubrace System provides the necessary support and stability for precast concrete walls during installation. This ensures that the walls remain in place and aligned until they are permanently secured.

Concrete Panels: For projects involving large concrete panels, the Accubrace System offers reliable bracing to maintain the panels' position and alignment, ensuring a smooth and efficient construction process.

Columns and Beams: The system can be used to brace columns and beams, providing the necessary support to prevent movement and misalignment during the construction phase.

Tilt-Up Construction: In tilt-up construction, where concrete elements are cast on-site and then tilted into position, the Accubrace System plays a crucial role in providing temporary support until the elements are fully secured.

In conclusion, the Accubrace System from Dayton Superior stands out as a premier bracing solution in the construction industry. Its combination of high-strength components, adjustability, ease of installation, and versatility makes it a valuable asset for any construction project. By enhancing safety, improving efficiency, and ensuring precise alignment, the Accubrace System helps construction professionals achieve optimal results with confidence.

Whether you are working on a small-scale residential project or a large commercial development, the Accubrace System offers the reliability and performance you need. For pricing or more information on the Dayton Superior Accubrace System, contact Mudge Fasteners at (800) 634-0406.

Dayton Superior Tilt-Up Handbook Product Guide

Dayton Superior has been at the forefront of innovation and excellence in the tilt-up concrete construction industry. With a rich history of developing essential hardware and systems, Dayton Superior continues to provide contractors with efficient, safe, and cost-effective solutions for lifting and handling concrete panels. Let's explore some of the standout products and systems from Dayton Superior that are crucial for tilt-up concrete construction.

Historical Contributions and Innovations

Dayton Superior's journey in the tilt-up construction sector began with the introduction of the embedded coil insert, a significant advancement that streamlined the process of lifting and positioning concrete panels. This innovation laid the groundwork for subsequent developments, including the Twist-Lift System in the mid-1960s, which was one of the simplest and most economical lifting systems at the time .

Ground Release Swift Lift System

One of the most notable advancements by Dayton Superior is the Ground Release Swift Lift System. This system enhances worker safety by allowing the lifting hardware to be released from the ground with a simple pull on a release line. This innovation eliminates the need for workers to climb ladders, significantly reducing the risk of falls and injuries .

Gyro Tilt Plus System

The Gyro Tilt Plus System is designed for efficiency and safety in lifting and handling tilt-up panels. Key components of this system include:

T50 Gyro Tilt Plus Hardware: This hardware ensures high safe working loads, ease of operation, and positive ground release, making it highly effective for tilt-up operations.

T51 Gyro Tilt Plus Shear Bar: This shear bar is crucial for developing the shear loads necessary for edge lift applications.

T52 Heavy Duty Gyro Tilt Plus Insert: Similar to the T49 insert, the T52 offers high load capacity due to its 1" diameter hot-forged anchor. It is designed for easy installation and reliable performance.

T53 Heavy Duty Gyro Tilt Plus Hardware: This hardware is used in conjunction with the T52 insert to lift, handle, and place heavy concrete panels efficiently .

Superior Lift Tilt-Up System

The Superior Lift Tilt-Up System is another cutting-edge solution from Dayton Superior, offering versatility and reliability for various panel lifting scenarios. This system is part of Dayton Superior's commitment to providing comprehensive solutions for tilt-up construction, ensuring both safety and efficiency on the job site.

Technical Assistance and Support

Dayton Superior goes beyond product innovation by offering extensive technical assistance to contractors. Their services include consultation and recommendations, panel erection details, wind bracing requirements, additional reinforcement, strongback requirements, rigging methods, and material takeoffs. This technical support is backed by years of experience and computer-aided design tools, ensuring precise and effective solutions for every project .

Dayton Superior's contributions to tilt-up concrete construction are unparalleled, with a wide range of products and systems designed to enhance safety, efficiency, and cost-effectiveness. From the pioneering embedded coil insert to the advanced Ground Release Swift Lift and Gyro Tilt Plus Systems, Dayton Superior continues to lead the industry with innovative solutions and comprehensive support.

For more information on Dayton Superior products and technical assistance, contractors can rely on their expertise to ensure successful and safe tilt-up construction projects. For pricing and more information, contact Mudge Fasteners at (800) 634-0406.

In the ever-evolving landscape of construction, the importance of reliable, innovative, and high-quality products cannot be overstated. For over a century, Dayton Superior has been at the forefront of providing cutting-edge solutions that meet the diverse needs of the construction industry. From concrete accessories to chemicals and formwork, Dayton Superior has become synonymous with excellence and dependability. Mudge Fasteners is proud to be an authorized distributor for Dayton Superior, and we’d like to introduce our customers to the wide range of products offered by Dayton Superior and how they can enhance your construction projects.

A Legacy of Innovation and Quality

Since its founding in 1924, Dayton Superior has been dedicated to developing products that improve the efficiency, safety, and quality of construction projects. With a focus on continuous innovation, the company has built a comprehensive portfolio that includes concrete accessories, chemicals, formwork, paving, and precast solutions.

Concrete Accessories: The Backbone of Strong Structures

Dayton Superior's extensive range of concrete accessories is designed to meet the highest standards of performance and durability. From bar supports and slab bolsters to form ties and rebar splicing systems, these products ensure that concrete structures are built to last. The company's bar supports, for example, are engineered to maintain precise rebar positioning, which is crucial for the structural integrity of concrete.

Chemical Solutions: Enhancing Performance and Longevity

To complement its concrete accessories, Dayton Superior offers a variety of chemical solutions that enhance the performance and longevity of concrete structures. These include curing compounds, sealers, bonding agents, and epoxy systems. The company's curing compounds, for instance, are formulated to retain moisture in freshly placed concrete, preventing cracks and ensuring optimal strength development.

Formwork Solutions: Precision and Efficiency

Formwork is a critical component of any concrete construction project, and Dayton Superior provides an array of formwork solutions that cater to different project requirements. Whether you need traditional wood forms, steel-ply forms, or innovative modular systems, Dayton Superior has you covered. These formwork systems are designed for ease of use, durability, and the ability to create precise shapes and finishes.

Paving Solutions: Building Roads to the Future

Dayton Superior's paving products are essential for constructing durable and long-lasting roads, highways, and other paved surfaces. The company's offering includes dowel bar systems, joint sealants, and curing agents, all of which contribute to the creation of smooth, resilient pavements. For example, their dowel bar systems ensure proper load transfer across pavement joints, reducing the likelihood of cracks and prolonging the life of the pavement.

Precast Solutions: Versatility and Efficiency

Precast concrete products are known for their versatility and efficiency, and Dayton Superior's precast solutions are no exception. The company's range includes lifting systems, connection hardware, and form liners, all designed to facilitate the production and installation of precast concrete elements. These products help streamline construction processes, reduce on-site labor, and improve overall project timelines.

Commitment to Sustainability

In addition to their product excellence, Dayton Superior is committed to sustainability and environmentally responsible practices. The company continuously seeks ways to reduce its environmental impact, from optimizing manufacturing processes to developing eco-friendly products that contribute to greener construction practices.

Dayton Superior's comprehensive range of products and solutions demonstrates the company's unwavering commitment to advancing the construction industry. By providing innovative, high-quality products that enhance the durability, efficiency, and sustainability of construction projects, Dayton Superior continues to be a trusted partner for professionals around the world. Whether you are working on a small residential project or a large-scale infrastructure development, you can rely on Dayton Superior to deliver the products and support you need for success.

For pricing or more information on Dayton Superior products, contact Mudge Fasteners at (800) 634-0406.

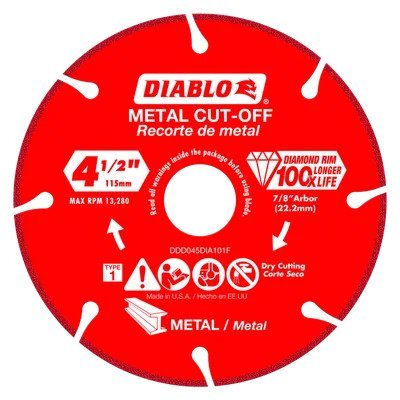

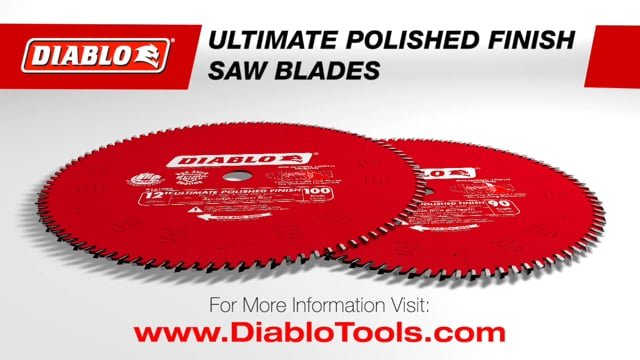

Witness the extraordinary in action. Explore Diablo Tools’ demonstration videos below that showcase the unmatched performance of their saw blades, hole saws, and abrasives. Discover firsthand how Diablo products surpass and outlast the competition with ease. Start with the "Why Diablo" video, unveiling the innovative engineering that sets a new standard in cutting technology. See for yourself how Diablo is reshaping the landscape of cutting tools.

Diablo stands apart as the sole manufacturer of its proprietary MicroGrain Carbide with Titanium, dubbed TiCo™, as well as its unique blend of Titanium and Cobalt, known as Hi-Density. Additionally, Diablo utilizes a specialized ceramic metallic tooth blend, Cermet II, tailored for stainless and mild steels. By exclusively producing and employing its own Carbide and Cermet II in all its products, Diablo possesses the distinctive capability to tailor each tool to precise applications, thereby optimizing both tool longevity and performance. This singular approach positions Diablo as a leader in offering specialized solutions and unparalleled performance across every application.

For pricing or more information on Diablo Tools products, contact Mudge Fasteners at (800) 634-0406.

In the realm of tools where precision meets power, craftsmanship merges with innovation, and excellence becomes a standard, Diablo Tools emerges as a titan among giants. Revered for its unwavering commitment to quality, performance, and reliability, Diablo Tools has become a go-to choice for discerning professionals and passionate craftsmen alike. Mudge Fasteners is proud to be an authorized distributor for Diablo products.

Products available from Diablo include:

Why choose Diablo prooducts? Several factors contribute to what makes Diablo Tools special:

Cutting-Edge Innovation: Diablo Tools consistently pushes the boundaries of innovation, introducing cutting-edge technologies that enhance performance, efficiency, and precision. Whether it's their advanced blade designs, state-of-the-art materials, or groundbreaking manufacturing techniques, Diablo Tools sets new standards for excellence in the industry.

Uncompromising Quality: From the selection of raw materials to the rigorous quality control processes, Diablo Tools spares no expense in ensuring the utmost quality in every tool they produce. This dedication to excellence results in tools that are not only durable and reliable but also capable of delivering consistently superior performance even in the most demanding applications.

Precision Craftsmanship: Diablo Tools understands the importance of precision in every task, whether it's cutting, drilling, sanding, or shaping. Their meticulous attention to detail and commitment to precision craftsmanship ensure that each tool is engineered to deliver precise, accurate results, empowering users to achieve perfection in their work.

Versatility and Adaptability: Diablo Tools offers a diverse range of products designed to tackle a wide variety of tasks across different trades and applications. Whether you're a woodworker, metalworker, contractor, or DIY enthusiast, Diablo Tools has the right tool for the job, providing unmatched versatility and adaptability to meet the evolving needs of professionals and hobbyists alike.

Exceptional Performance: Ultimately, what sets Diablo Tools apart is their exceptional performance. Whether it's the smooth, effortless cuts of their saw blades, the aggressive sanding action of their abrasives, or the fast, clean drilling of their drill bits, Diablo Tools consistently outperforms the competition, delivering results that exceed expectations and inspire confidence in users.

In summary, Diablo Tools' combination of cutting-edge innovation, uncompromising quality, precision craftsmanship, versatility, and exceptional performance make them a standout choice for professionals and enthusiasts seeking tools that elevate their craft and enable them to achieve unparalleled results.

For pricing or more information on Diablo Tools, contact Mudge Fasteners at (800) 634-0406.

Welcome to the realm of high-level security fasteners, where every bolt and screw stands as a fortress against unauthorized access and tampering. These fasteners boast theft-resistant and tamperproof designs meticulously crafted to thwart even the most determined intruders. In a world where the protection of valuable assets and sensitive equipment is paramount, these fasteners serve as the first line of defense, offering unparalleled security and peace of mind. The following are a dozen featured high security fasteners that Mudge Fasteners offers:

Tri-Wing

Tri-Wing fasteners feature three slots arranged in a triangular pattern. They are commonly used in electronics, such as gaming consoles and gadgets, to deter unauthorized disassembly or modification.

OPSIT Reverse Thread

OPSIT fasteners have a reverse thread design, requiring a special tool to loosen them. They find utility in applications where traditional fasteners might be easily compromised, such as securing access panels in high-security facilities or equipment.

TP3

The TP3 screw features a trilobular drive that necessitates a corresponding tool for installation. To enhance security measures, the matching tools are exclusively available to purchasers of the TP3 screw directly from the manufacturer, Tamperproof.

Lock-Out

Lock-Out fasteners utilize a unique locking mechanism, making them ideal for applications where frequent maintenance is required, but security must not be compromised. They are commonly used in industrial machinery and equipment.

Key-Rex

Key-Rex screws feature a patented drive design that requires a matching key for installation and removal. They are extensively utilized in public infrastructure, signage, and utilities to prevent vandalism and theft.

Penta-Plus

Penta-Plus screws have a five-pointed drive, offering increased security compared to traditional fasteners. They are often employed in sensitive environments like prisons, airports, and military installations.

Stykfit-7

Stykfit-7 fasteners feature a unique thread profile that resists vibration and loosening. They are favored in aerospace and automotive applications where fastener integrity is critical for safety.

Strip-Lok

Strip-Lok screws have a tamper-resistant design that prevents removal with standard tools. They are commonly used in public infrastructure, utility meters, and electrical panels.

Roby Pin

Roby Pin fasteners incorporate a central pin that must be aligned correctly for installation or removal. They are popular in retail, securing high-value merchandise and display cases.

Ultra 5-Lobe

Ultra 5-Lobe screws have a five-pointed lobular drive, providing enhanced security against tampering. They find applications in consumer electronics, medical devices, and aviation.

Avsafe

Avsafe fasteners are specifically designed for aviation applications, meeting stringent safety and security requirements in aircraft construction and maintenance.

Ultra-Lok II

Ultra-Lok II screws feature a unique drive system with multiple points of engagement, offering superior resistance to tampering. They are commonly used in access control systems, security fencing, and public infrastructure.

If you need pricing or more information on any of these high level security, theft resistant, tamper-proof fasteners, contact Mudge Fasteners to speak with one of our helpful fastener experts at (800) 634-0406.

In a world where security is paramount, every nut and bolt matters. But not all nuts are created equal. Some serve a more specialized purpose – to safeguard valuable assets and prevent unauthorized access. Enter the realm of security nuts – a diverse array of fasteners designed to thwart tampering and ensure the integrity of your belongings. Let's delve into the world of security nuts, exploring their unique designs and applications.

Key-Rex Nuts

Key-Rex nuts are characterized by their unique five-sided socket design, which requires a matching key for installation and removal. This proprietary design makes it extremely difficult for unauthorized individuals to tamper with secured equipment, providing enhanced security in various industries, including telecommunications, transportation, and infrastructure.

Penta-Plus Nuts

Similar to Key-Rex nuts, Penta-Plus nuts feature a pentagon-shaped recess, making them resistant to standard tools and requiring a specialized key for installation and removal. These high-security fasteners are commonly used in applications where safeguarding against vandalism and theft is critical, such as public utilities and outdoor fixtures.

Ultra-Lok S7 Nuts

Ultra-Lok S7 nuts boast a seven-sided socket configuration, offering even greater resistance to tampering compared to traditional hexagonal nuts. This advanced design provides enhanced security for sensitive equipment and infrastructure, deterring unauthorized access and safeguarding against malicious threats.

Tri-Groove Nuts

Tri-Groove nuts, also known as T-Groove or Trident nuts, feature a triangular recess with three rounded grooves, requiring a specialized driver for installation and removal. Despite their simple appearance, these fasteners offer robust security, making them suitable for a wide range of applications, including automotive, manufacturing, and construction.

Spanner Nuts

Spanner nuts, also referred to as security nuts or snake eye nuts, feature a unique two-hole design that requires a specialized spanner tool for tightening and loosening. This unconventional configuration enhances security by preventing tampering with essential components, making spanner nuts ideal for use in machinery, signage, and access panels.

T-Slope Nuts

T-Slope nuts feature a sloped internal profile with a T-shaped groove, requiring a matching driver for installation and removal. This innovative design provides enhanced security against unauthorized access and tampering, making T-Slope nuts well-suited for applications where asset protection is paramount, such as electronic enclosures and industrial equipment.

In conclusion, security nuts play a crucial role in safeguarding valuable assets and infrastructure against tampering, theft, and vandalism. From Key-Rex and Penta-Plus nuts to Ultra-Lok S7 and Tri-Groove nuts, each type offers unique features and benefits tailored to specific security needs. By understanding the diverse range of security nut options available, businesses and organizations can make informed decisions to enhance the protection of their assets and maintain peace of mind in an ever-changing world.

For more information about security nuts or to speak with someone who can help you choose which would be best for your application, contact Mudge Fasteners at (800) 634-0406.

In the world of construction, electronic equipment, or even industrial manufacturing, security fasteners play a vital role in ensuring safety, security, and sometimes, secrecy. These specialized screws aren't just your run-of-the-mill hardware; they are designed to thwart tampering, theft, or unauthorized access. Let's delve into the diverse world of security fasteners, understanding their unique features and the scenarios where they shine.

Machine Screws

Machine screws are a staple in securing metal parts together. What sets them apart in the realm of security is their compatibility with various security drive styles like torx with pin, hex with pin, or one-way heads. These heads make it challenging for unauthorized individuals to remove or tamper with the screws, ideal for safeguarding expensive equipment, access panels, or electronic enclosures.

Sheet Metal Screws

As the name suggests, sheet metal screws are tailored for fastening metal sheets. Their sharp threads and self-tapping abilities make them perfect for applications where conventional screws might struggle to grip. In security applications, these screws with specialized drives offer added protection against tampering, making them ideal for securing license plates, signage, or even HVAC systems.

Self-Drilling Screws

Self-drilling screws are a marvel of engineering, designed to eliminate the need for pre-drilling holes. Their sharp tips can pierce through materials like metal or wood with ease. In security contexts, these screws come equipped with tamper-resistant heads, ensuring that once installed, they stay put, making them invaluable for securing machinery, outdoor fixtures, or even in critical infrastructure projects.

Lag Screws

Lag screws, known for their robustness and holding power, are commonly used in heavy-duty applications such as construction and woodworking. Their coarse threading and thick shafts make them ideal for anchoring heavy loads to wood or metal. When outfitted with security drive heads, they become an impenetrable barrier against tampering, making them indispensable in securing gates, fences, or equipment in public spaces.

Miniature Security Screws

In scenarios where space is limited, and precision is paramount, miniature security screws step up to the plate. These tiny fasteners pack a punch in terms of security, often featuring intricate drive patterns that are nearly impossible to manipulate without specialized tools. From securing delicate electronics to safeguarding jewelry or optical devices, miniature security screws offer a discreet yet robust solution.

To learn more about these security fasteners, or to request pricing, contact Mudge Fasteners at (800) 634-0406.

When it comes to securing valuable assets or deterring unauthorized access, the choice of fasteners plays a pivotal role in fortifying defenses. Standard drive types in security fasteners offer a diverse array of solutions tailored to specific security needs. From the unidirectional protection of One-Way screws to the intricate designs of 6-Lobe with Pin fasteners, each drive type serves as a barrier against tampering and unauthorized entry. In this comprehensive guide, we delve into the world of security fasteners, exploring popular options such as Spanner, Hex Socket with Pin, Security Phillips, and Tri-Groove, elucidating their unique features and applications in safeguarding critical infrastructure and assets.

One-Way

A one-way drive in a screw is a specialized type of fastener designed to offer enhanced security by allowing installation in one direction only. These screws feature a unique head design with slanted or ramped grooves that enable easy insertion when turned in a specific direction but make removal exceptionally difficult or near impossible. The concept behind one-way drives is simple yet effective: while they can be easily tightened with a standard tool, such as a screwdriver or drill, attempting to loosen or remove them without the corresponding tool or in the reverse direction results in the screw's head slipping or binding against the surface, thwarting unauthorized tampering or removal attempts. One-way screws are commonly used in applications where preventing vandalism, theft, or unauthorized access is paramount, such as securing access panels, license plates, or public fixtures.

Spanner

A Spanner drive in a screw, also known as a Snake-Eye or Pig-Nose drive, is a type of security fastener distinguished by its unique head design. Instead of traditional slots or recesses, Spanner screws feature two small holes or recesses set opposite each other in the screw head. These holes are typically shaped to accommodate a specialized tool called a Spanner or Snake-Eye bit, which has two prongs or pins that fit into the corresponding holes.

The Spanner drive design provides increased security by requiring a specialized tool for installation and removal, making it more difficult for unauthorized individuals to tamper with or access the secured item. The drive's unconventional shape and requirement for a specialized tool enhance security and deter tampering, making Spanner screws popular choices for applications where preventing vandalism, theft, or unauthorized access is crucial, such as in public infrastructure, electronic enclosures, or machinery.

Hex Socket with Pin

A Hex Socket with Pin drive in a screw is a type of security fastener designed to provide enhanced tamper resistance. These screws feature a hexagonal socket (also known as an Allen or Hex socket) in the head, which requires a corresponding hex key or Allen wrench for installation and removal. However, what sets Hex Socket with Pin screws apart is the addition of a small pin in the center of the socket.

The pin in the Hex Socket with Pin drive acts as an additional security measure by obstructing the insertion of standard hex keys or Allen wrenches. Instead, a specialized tool with a hole or groove to accommodate the pin is required for installation and removal. This design significantly increases the level of security, as it prevents unauthorized individuals from easily accessing or tampering with the fastener.

Hex Socket with Pin screws are commonly used in applications where heightened security is necessary, such as in machinery, electronic enclosures, automotive components, and high-security installations. Their combination of a familiar drive type with an added pin mechanism makes them an effective deterrent against tampering and unauthorized access.

6-Lobe with Pin

A 6-Lobe with Pin drive in a screw is a type of security fastener designed to provide high levels of tamper resistance and security. Also known as Torx with Pin or Star with Pin, this drive type combines the familiar six-pointed star-shaped recess (6-Lobe or Torx) with an added pin in the center.

Similar to other security fasteners, the inclusion of the pin in the 6-Lobe with Pin drive prevents standard tools from engaging with the screw head. Instead, specialized tools with a corresponding hole or groove to accommodate the pin are required for installation and removal.

The 6-Lobe drive pattern itself offers several advantages, including increased torque transmission and reduced cam-out, which occurs when the driver slips out of the screw recess under high torque. When combined with the added security of the pin, 6-Lobe with Pin screws become an effective deterrent against tampering, theft, and unauthorized access.

These screws are commonly used in a wide range of applications where security is paramount, such as in electronic devices, automotive components, machinery, and critical infrastructure. The combination of the unique 6-Lobe drive pattern and the added pin mechanism ensures that only authorized personnel with the appropriate tools can access or manipulate the fasteners, enhancing overall security.

Security Phillips

A Security Phillips drive in a screw is a type of fastener designed to provide an additional level of security compared to standard Phillips head screws. While Phillips head screws are widely used and easily installed and removed with a standard Phillips screwdriver, Security Phillips screws feature a modified head design for increased tamper resistance.

The Security Phillips drive typically includes a protrusion or post in the center of the screw head, which obstructs the insertion of a regular Phillips screwdriver. Instead, a specialized tool with a corresponding shape, such as a Security Phillips bit or driver, is required for installation and removal.

This unique design deters unauthorized access and tampering, making Security Phillips screws suitable for applications where preventing vandalism, theft, or unauthorized access is crucial. They are commonly used in various industries, including electronics, automotive, manufacturing, and public infrastructure.

Overall, Security Phillips screws offer a simple yet effective solution for enhancing security, ensuring that only authorized individuals with the appropriate tools can access or manipulate the fasteners.

Tri-Groove

A Tri-Groove drive in a screw is a type of security fastener distinguished by its unique head design, which consists of three shallow slots or grooves arranged in a triangular pattern. This drive type is also known as Trident or Conedrive.

Tri-Groove screws are designed to provide enhanced security by requiring a specialized tool, known as a Tri-Groove driver or socket, for installation and removal. The driver features three prongs that match the configuration of the grooves on the screw head, allowing for engagement and manipulation.

The triangular shape of the grooves offers several benefits, including increased resistance to tampering and removal attempts. Additionally, the shallow nature of the grooves makes it challenging for standard tools to engage with the screw head effectively, further enhancing security.

Tri-Groove screws find application in a variety of industries where preventing unauthorized access, tampering, or theft is essential. Common uses include securing access panels, signage, utilities, and public infrastructure.

In summary, Tri-Groove screws provide an effective solution for enhancing security, ensuring that only individuals with the appropriate tools can access or manipulate the fasteners.

If you need assistance in choosing which security fastener drive is right for you, contact Mudge Fasteners at (800) 634-0406 for help.

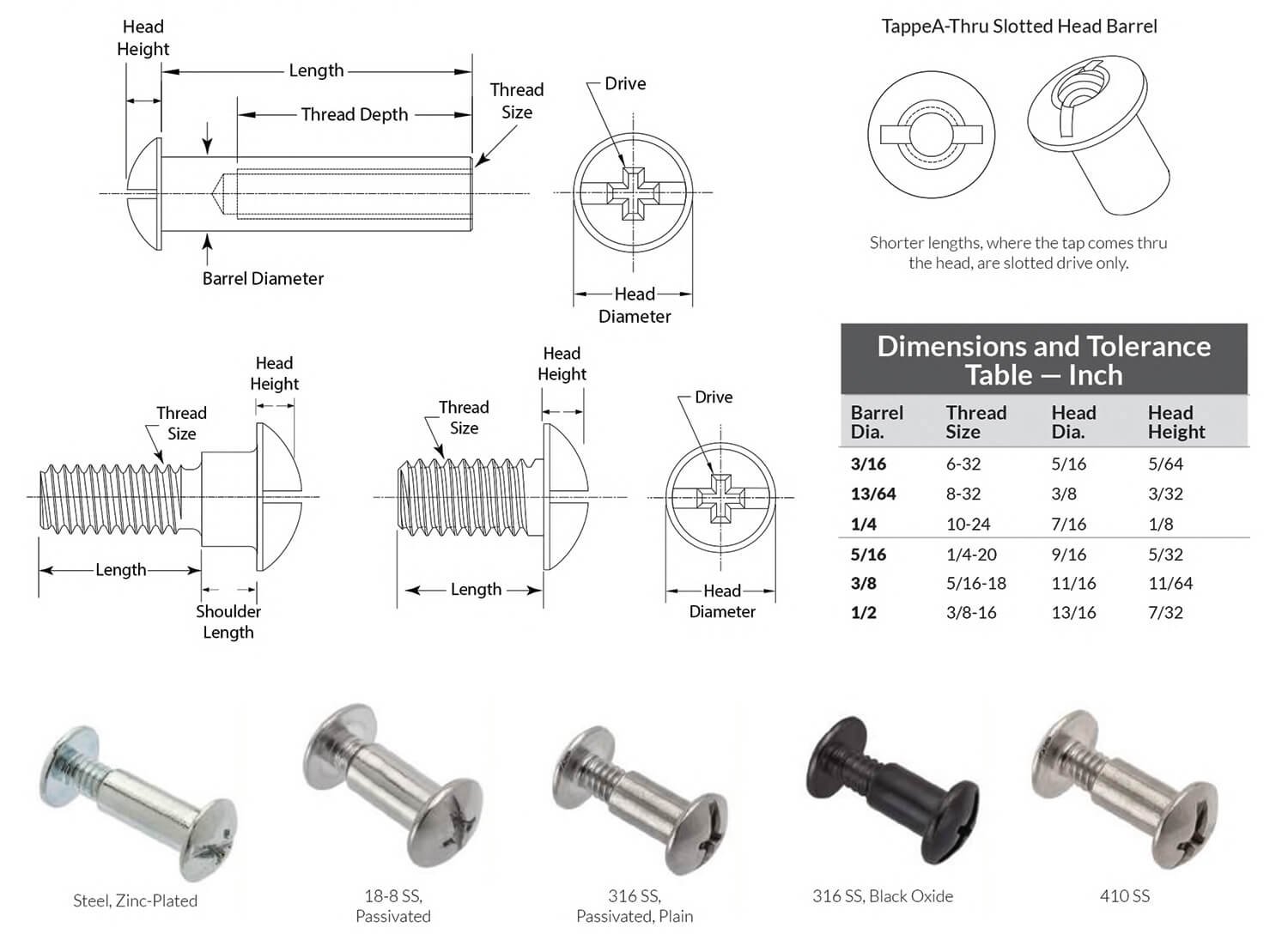

Combo Drive Barrels and Screws are a type of mating fasteners that collaborate to secure a specified length between the barrel's head and the mating screw's head, such as within a hollow door. Binding Posts and Screws find frequent application in conjunction with round or square metal tubes or pipes.

Within this extensive assortment of Combo Drives, the truss-style head stands out, presenting a broader and lower profile compared to the conventional round head. This unique head features a versatile combination drive, incorporating a combination slot and Phillips. The truss head design is specifically engineered to distribute holding pressure, thereby reducing the risk of crushing in thin and softer materials. Additionally, it provides an increased bearing surface, enhancing overall holding power. The screws adhere to a class 2A fit.

Combo Drive Barrels and Screws are offered in the following materials and finishes:

Steel: Zinc-Plated Finish, Zinc-Black Finish, Black Oxide Finish

18-8 Stainless Steel: Passivated

316 Stainless Steel: Passivated, Plain Finish, Black Oxide Finish

410 Stainless Steel: Thru Hardened

For more information or pricing on combo drive barrel and screws, contact Mudge Fasteners at (800) 634-0406.

Mating fasteners, also known as Chicago screws, barrel nuts, or post and screw fasteners, are a type of fastening solution used to join two or more materials securely. They consist of two components: a male screw (post) and a female barrel, which has an internally threaded hole. When assembled, the male and female parts combine to create a robust and tamper-resistant connection.

The choice of materials used in barrel bolts plays a pivotal role in their performance and durability. From the robust strength of stainless steel to the lightweight versatility of aluminum, the materials used in barrels and screws can significantly impact their functionality in various applications.

In this article, we delve into the diverse options available, examining the unique properties of each material and the factors to consider when selecting mating fasteners for specific needs.

Aluminum

Aluminum boasts the strength equivalent to mild steel but is only one-third of the weight, making it an ideal choice for various applications. It demonstrates remarkable resistance to corrosion in wet environments and is commonly employed for fittings, hardware, and fasteners. Additionally, it possesses nonmagnetic properties.

Brass

Brass, composed of approximately two-thirds copper and one-third zinc, is a relatively softer material. It offers good resistance to rust and atmospheric corrosion, making it suitable for use in gears, bearings, fasteners, and valves. Furthermore, brass exhibits nonmagnetic characteristics.

Copper

Copper, known for its versatility and durability, finds applications in various fields. Its distinctive color is particularly favored by artists and architects for its decorative finish. This electrically conductive material boasts excellent thermal properties, is nonmagnetic, and resists rust in wet environments.

Stainless Steel 18-8 (303)

Type 303 stainless steel provides excellent corrosion resistance and is resilient against chemicals, most dyes, food, and nitric acid. Widely used for screws, bushings, nuts, and hardware, it may exhibit mild magnetic properties.

Stainless Steel 316 (316/316L)

Type 316 stainless steel surpasses Type 303 in terms of corrosion resistance. It effectively resists saltwater, acids, chlorides, alkalis, and various industrial solvents. This low-maintenance material is commonly utilized in commercial kitchens and food processing, with a possibility of mild magnetic behavior.

Stainless Steel 416

Type 416 stainless steel can achieve hardness up to Maximum Rockwell C40 after heat treatment. It resists acids, alkalis, fresh water, and dry air, making it a non-galling and hardenable material suitable for fittings, gears, shafts, and screws. This type of stainless steel is magnetic.

Low Carbon Steel

Low Carbon steel is employed in numerous general-purpose applications. To resist rust, it requires a finish such as black oxide treatment or zinc plating. Commonly used for binding posts, bushings, washers, inserts, fittings, screws, and nuts, this material exhibits magnetic properties.

If you need assistance determining which type or material of mating fasteners works best for your application, contact Mudge Fasteners at (800) 634-0406.