Lindapter Hollo-Bolt Featured in German Solar Car Charging Stations

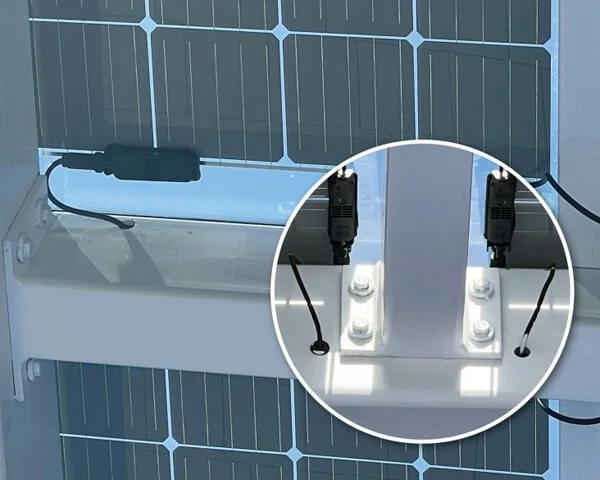

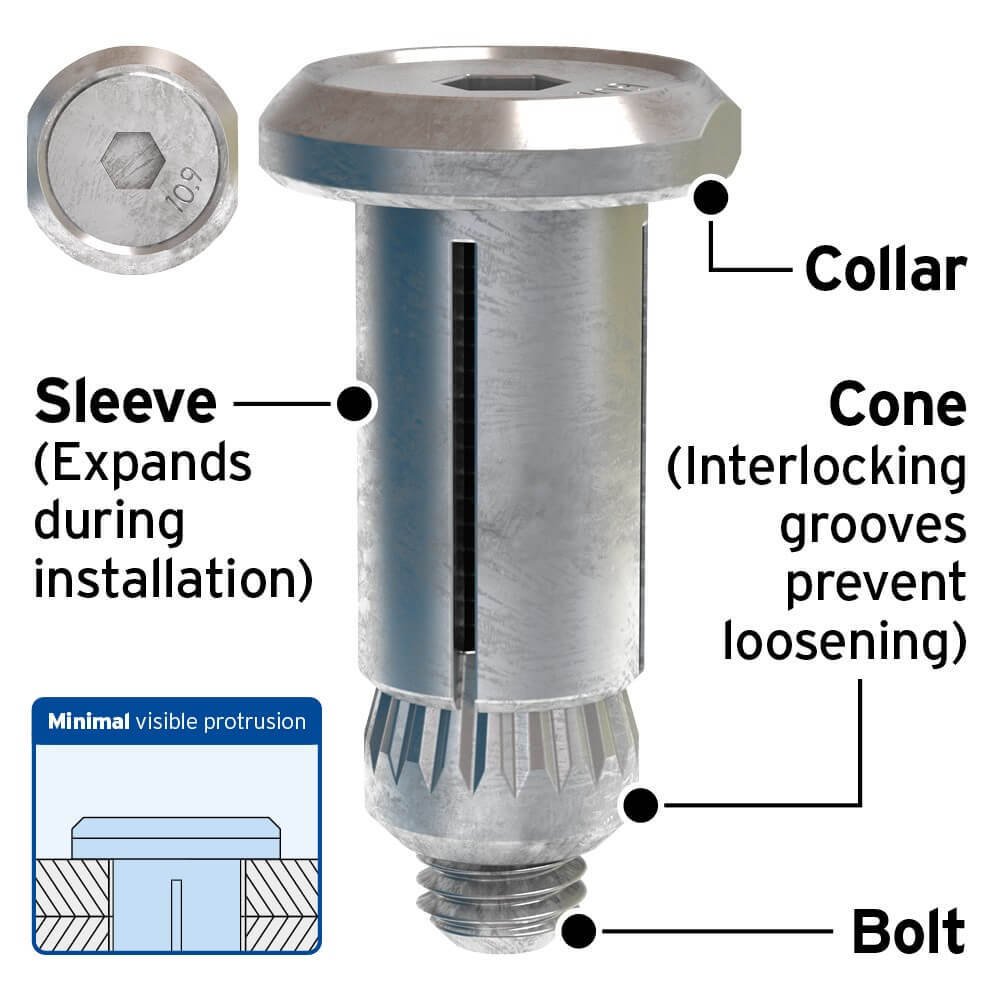

Lindapter’s technical support team worked with the client in order to design a suitable connection using Hollo-Bolt, the original expansion bolt for structural steel that requires access to only one side of the HSS. The design incorporated splice connections with pre-drilled holes in the HSS which the Hollo-Bolt could be inserted through to join the roof framework together. Hollo-Bolt Countersunk and Flush Fit head types were specified in critical locations to prevent the heads obstructing the solar panels whilst Hexagonal head Hollo-Bolts were used in less critical locations in the roof framework. A Sheraplex coating was also specified for the Hollo-Bolts to provide a high level of corrosion protection.

The hollow structural sections were manufactured in a fabrication shop where they were cut to length, and holes drilled to suit the requirements of the Hollo-Bolts. The HSS was also galvanized prior to delivery to reduce labor costs and time in the field whilst also ensuring long lasting corrosion protection. Once in the field each finished and coated part was assembled by simply inserting the Hollo-Bolts into the predrilled holes and tightening them with a wrench to the recommended tightening torque. To complete the installation, solar panels were connected to the framework and then the whole roof hoisted into position on steel support columns.

For more information on Hollo-Bolt and other EV Charging fasteners, contact us at (800) 634-0406.