Steps to Designing a Fastener Kit

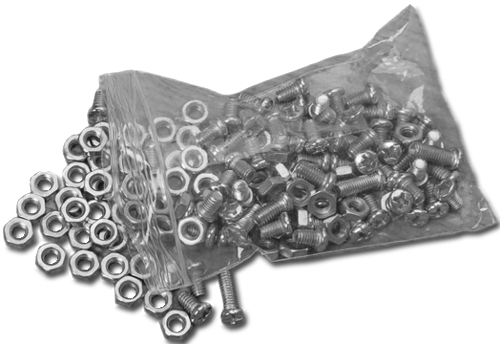

One of the most popular services we offer at Mudge is custom kitting, meaning we’ll package our fasteners into kits with other materials of your choosing. These are often used in products where assembly is required by the end user, or where in-field personnel would save time by having their parts already kitted into one package. Sometimes, the kit becomes a salable on its own, such as in the case of skateboard hardware.

If you’re thinking about designing a fastener kit for use in your products or your business operations, there are several factors to consider, but the main three are quantity, contents of the kit, and packaging.

The first factor to consider when considering kitting up your fasteners is the quantity you’ll be purchasing. This takes more thought than it would when you’re buying and sending out parts individually, because you can only stock and ship complete kits. Additionally, kitting has lead times, as do many items within the kits, so it’s important to plan ahead and error on the side of over-ordering rather than under-ordering. One question to ask yourself when considering kit quantities is “If my business increases significantly, will we have enough kits to keep up with demand?”

The next, and most obvious factor to consider when designing a kit is what will be inside the kit. If you’re working with Mudge, you’re including some sort of fastener, but we can also take your other parts to include in the kit as well. Anything from solar racking parts to injection molded plastic parts can be kitted with fasteners, adhesives and more. Don’t forget to consider what types of printed materials (assembly instructions, kit contents, etc.) that need to be included.

The final decision to be made when designing your kit is the type of packaging it will be in. Some common options are poly bags, paperboard boxes and clamshell plastic packaging. You’ll want to consider the packaging’s cost, appearance and sizing before making any decisions. If you use a box, will it fit properly in the master case with your other components? If the kit is not going to be seen by customers prior to purchase, your most affordable option will be a standard, heat sealed poly bag. Acquiring a sample of your desired packaging will be best, but a photo or drawing may be helpful as well.

As you can see, there are a variety of decisions to be made when designing and ordering a custom fastener kit, but Mudge Fasteners is here to help you all along the way. Contact us at (800) 634-0406 to discuss your next steps in getting a custom kit designed for your business.